ABROAD SCOPE

Carey, together with Anthony Russo from Technical Audio Group, Martin Audio’s representative, made several visits to WHC to evaluate the scale of the project, create a design that would meet the brief’s requirements, and assure the church that this would be a unique partnership.

From Carey’s viewpoint, “This project was one of the most difficult I had ever worked on. We faced several challenges, from working at 15m heights for PA rigging to custom steel fabrication on site. Additionally, we had to install several kilometres of cables through a complex roof structure. Also, much of the fabrication had to be done in Australia with no room for error once the project was containerised and sea freighted.”

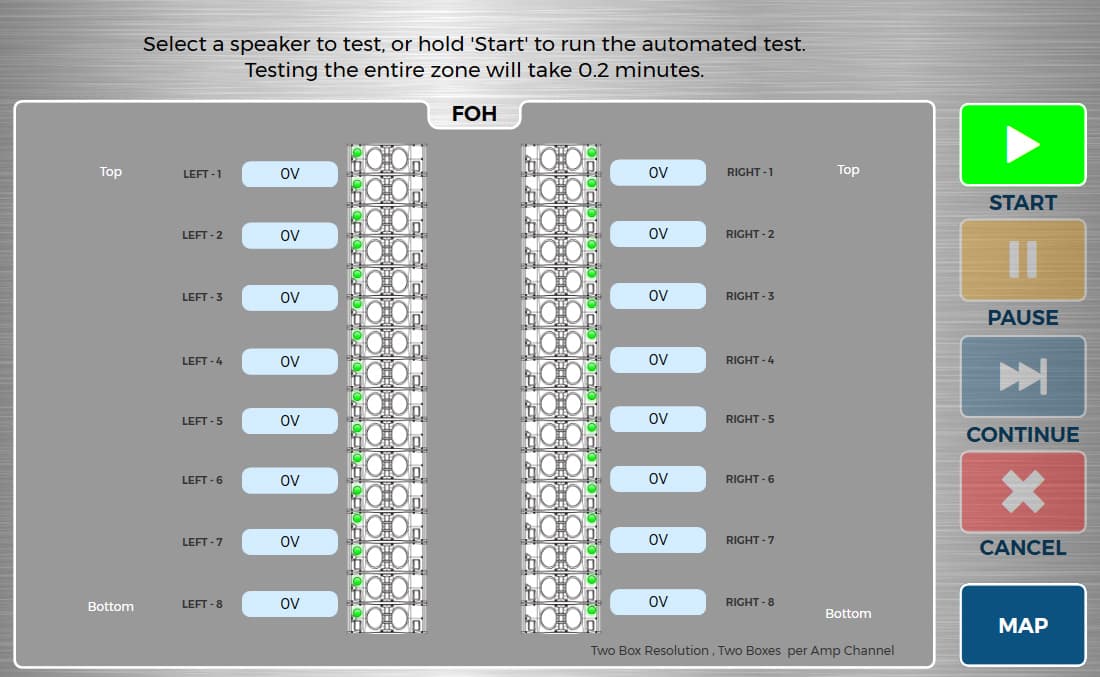

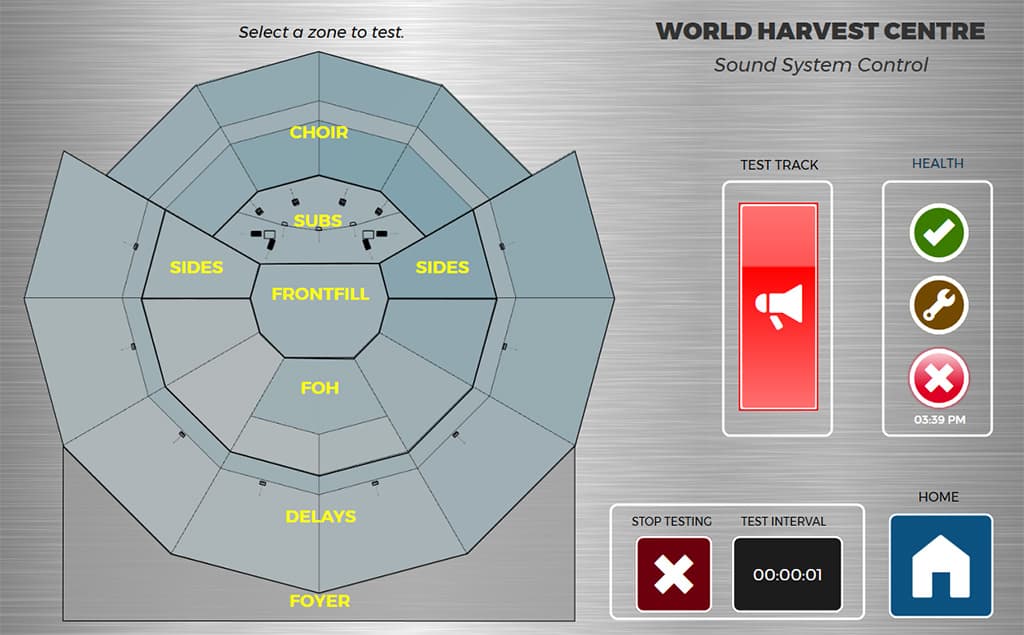

Choosing the final speaker design of the system involved hundreds of hours of modelling, with the final decision to use a Martin Audio WPM line array system with processing and amplification from a Q-SYS System. The church preferred to retain and improve some of the existing Q-SYS backbones and converge them with the Martin Audio system.

Anthony takes up the project overview: “During my many visits to the church, I sat in on many services and envisioned the many aspects of the system design and how to conquer the space. Moreover, I was emotionally moved by how much effort and love this space intertwines with every congregation member’s life.”

The services are major concert events with 3000-plus people singing, supported by a full band and choir. Therefore, the system had to achieve higher than normal SPLs and provide a unique experience generally associated with an international touring act.

“I believe every seat needs to be the best seat, all while trying to keep an eye on a budget. There is a fine line where you can’t compromise,” says Anthony.